Fixing Industrial Productivity: How AI Will Revitalize Our Workforce

Understanding the role of AI in enhancing efficiency and empowering workers in the industrial sector.

We have a problem. Demand for national production is increasing. But the availability of skilled labor in the industrial sector is decreasing.

We cannot recruit and train a new workforce overnight.

What can we do? Make our workforce more productive.

Solving the Industrial Productivity Problem

Our industrial sector (ex-construction) thrived in the 1990s-2000s but stagnated 15 years ago. Unfortunate, yes, but a great opportunity for innovation today.

An underinvestment in technology is one reason for this stagnation. Some industrial segments are the slowest adopters of software. Others are underserved; a majority of core operating systems used by these companies have been around since the 1980s.

This is changing.

An Industrial Rennaissance is coming. With the advent of mass AI adoption, these sectors will adopt new technology at rates not seen since the 90s.

Of course, one's mind immediately goes to dark factories, autonomous trucks, and robotic construction. This is the wrong way to think about it.

The transition will be iterative. It will work within current systems. It will leverage the strengths of today's workforce. In doing so, we will usher in a wave of productivity, resiliency, and unlock new capabilities.

Operating at “top of license”

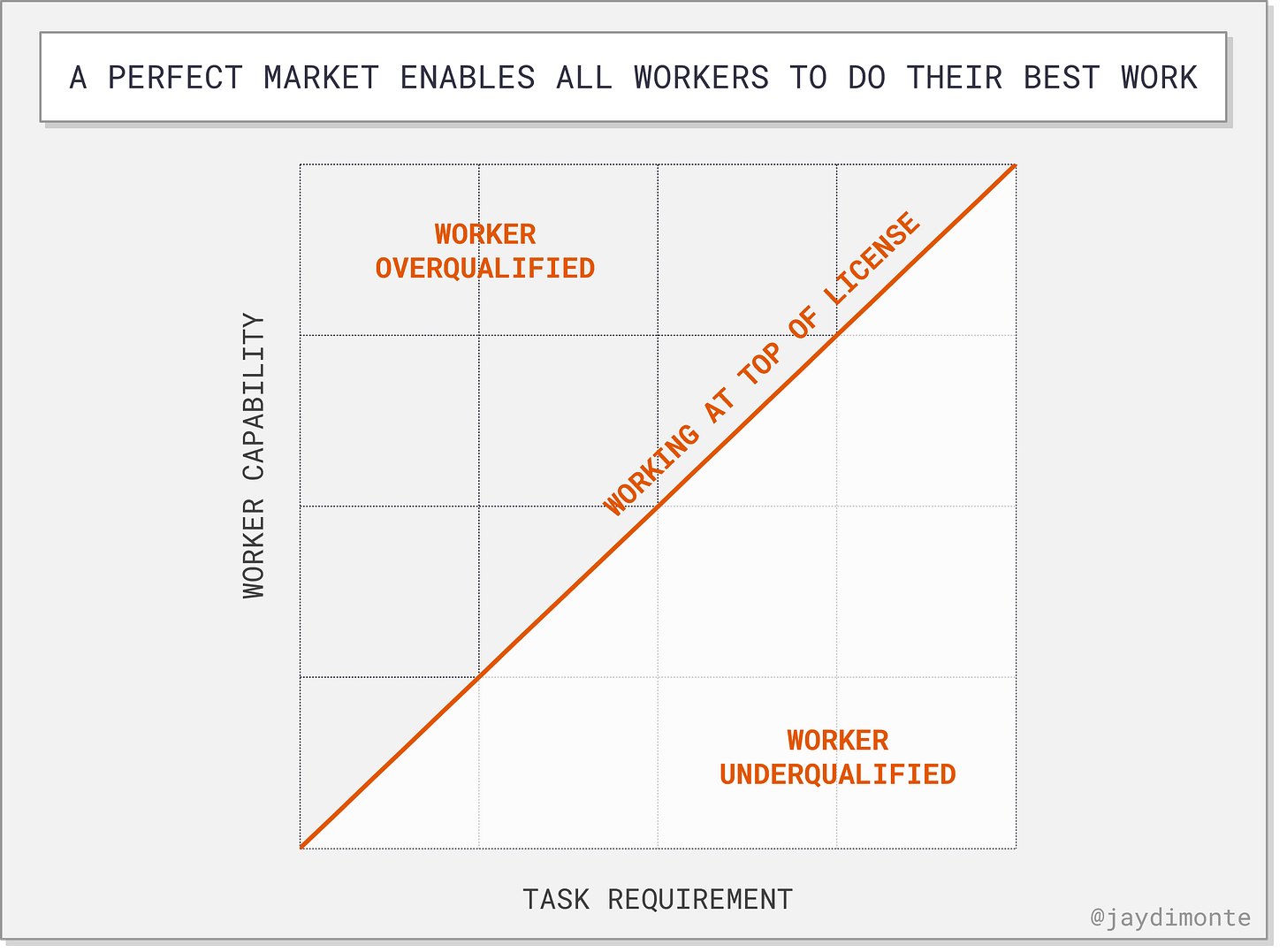

There is a concept in the healthcare, working at “top of license.” Every worker should spend their time doing the most impactful work that they are licensed to do. It is the reason a nurse takes your vitals when you visit a doctor’s office, and not the MD.

This concept applies to the industrial sector too.

For example, a Master Electrician may design a system that a Journeyman installs.

For example, an experienced Certified Welder may handle custom fabrication. A novice might cut their teeth on repetitive production line work.

It’s best for markets, firms, and workers when everyone operates at “top of license.”

If a worker is underqualified, their output may be too slow or done with low quality. If overqualified, the firm may be overpaying, or the worker may be undercompensated.

Requirements for Operating at “Top of License”

For a marketplace to ensure all workers operate at top of license, we need three things. We must have enough workers, they must work on the right tasks, and they must be able to do them well.

Quantity: We need the right number of workers to complete all work. Too many workers and wages stagnate. Too few, work is incomplete. Trade schools, universities, and apprenticeship programs address this.

Liquidity: We need to identify worker's capabilities and the work's requirements and make sure they match. Tech companies are well suited to address this problem. They develop better infrastructure for identifying, codifying, and managing our workforce. This manifests as marketplaces, workforce management SaaS, among others.

Maturity: We need to account for the variability of output by different workers. For example, if there is a job that you trust only "Jill" to do, what happens when she quits or retires? This is a hard problem to solve. How do you ensure that a novice can step in to complete an expert's work?

I am very excited for how AI can elevate our workforce by helping them work on the things that matter and do it at expert levels.

Enhancing Workforce Capabilities with AI

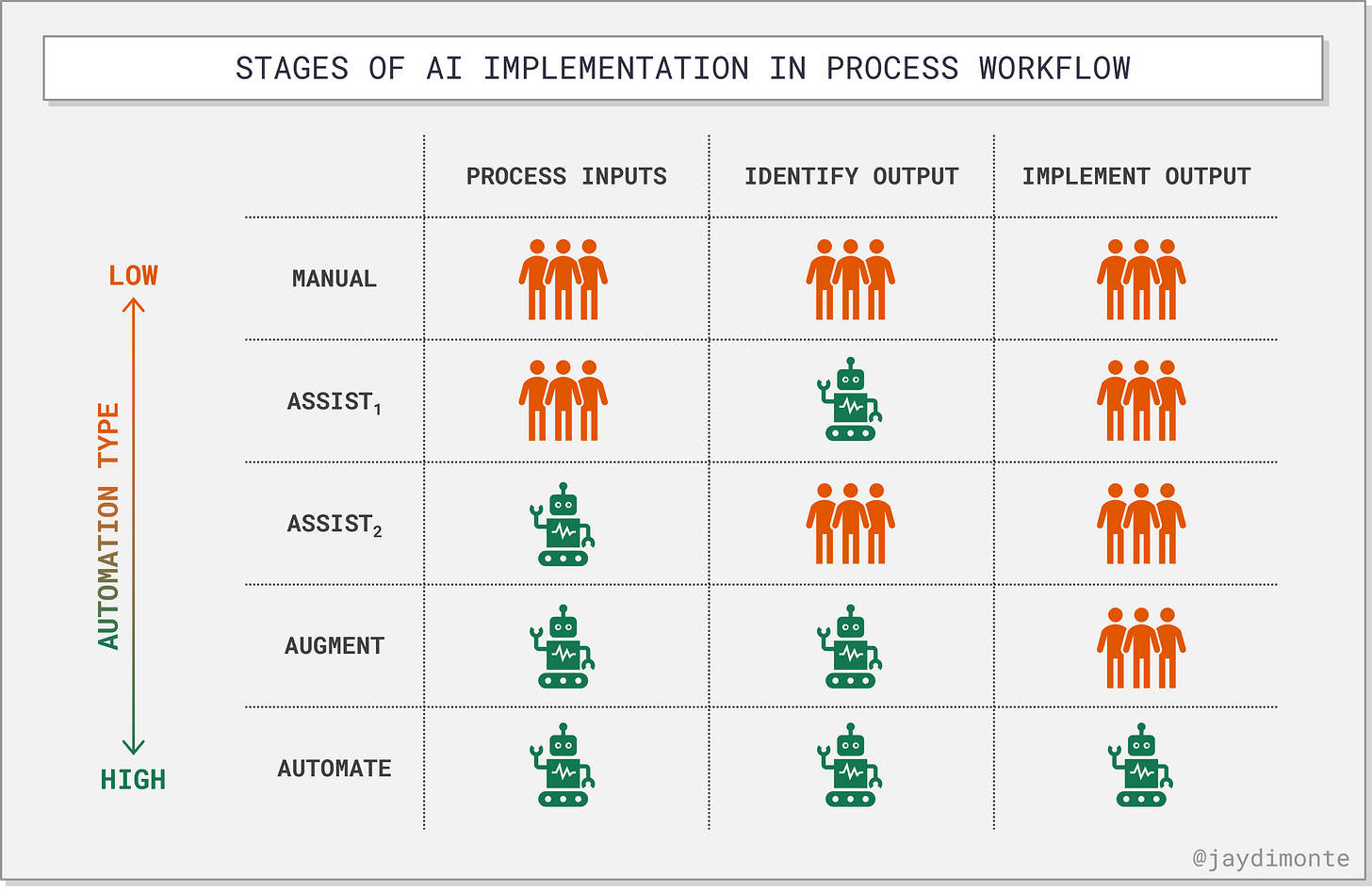

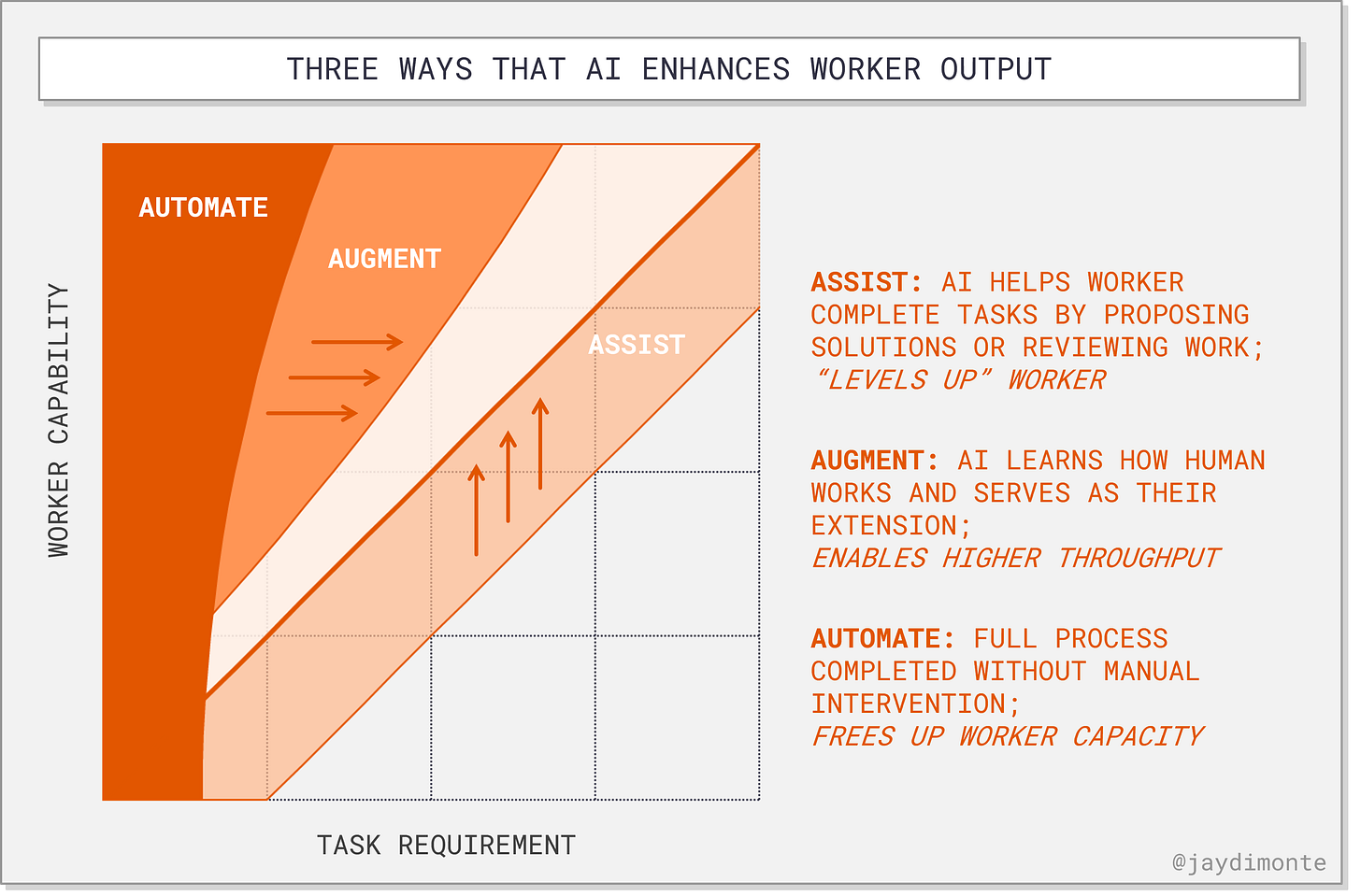

There are three ways AI helps us work better:

AI assists workers - Workers complete most of the task but AI reviews for correctness or speeds up the work.

AI augments workers - AI learns how worker works and replicates it, serving as an extension.

AI automates work - AI runs autonomously, completing tasks without supervision or intervention

Here are two examples to illustrate. In the first, a novice is able to perform at a higher level with AI’s assistance. In the second, an expert who is able to spend more time at “top of license” with AI augmentation and use of automation.

For example, a novice in quality assurance

Quality control technician Ted works for a manufacturer. He inspects finished products.

Manual process: Ted refers to quality control plans and technical drawings. He visually inspects the product. He documents and measures defects. It takes Ted four hours to inspect a product.

AI assists: Ted inspects the product. When he thinks he has found a defect, he takes a picture and AI says “yes” or “no.” It takes Ted two hours to inspect a product with AI's help. Over time, he learns from AI's confirmations and continues to reduce his cycle time.

AI augments: Ted takes pictures continuously while inspecting the product. The AI stops him when it identifies a defect and Ted takes a closer look. It now takes Ted only 30 min to complete the inspection.

AI automates: The manufacturer installs a robotic arm to inspect the product. Ted no longer works as a QC tech and has been retrained to maintain the robot.

When AI assists Ted, he performs at a higher level than he does unassisted. AI assistants can “level up” novice workers.

For example, an expert in supply chain

Supply-chain Suz works for the same manufacturer. She places orders for parts with suppliers. She tracks their progress to delivery so she can maintain a production schedule.

Manual process: Suz emails suppliers each day for a status update. They email her back and she updates various systems and updates the schedule.

AI assists: Suz emails suppliers. They email her back. AI structures the data in a common format and alerts her if the data is as expected to she can update the schedule.

AI augments: Suz emails suppliers. They email her back. AI assesses the responses and suggests updates to the schedule.

AI automates: AI emails suppliers, processes the responses, identifies issues, maintains the schedule. Suz coordinates with production and troubleshoots issues with suppliers (no one listens to AI threats just yet!).

These examples build on each other in a very clean way. Reality is a bit messier.

It's important to consider what type of automation is best suited for any particular customer and use-case.

Identifying the Right AI Applications for Industrial Sectors

There are three considerations to that determine if your AI application should assist, augment, or automate.

Infrastructure readiness

Cultural readiness

Cost/benefit considerations

Infrastructure readiness

Before an organization can adopt an AI application, it needs the right data and workflow.

In lieu of sufficient infrastructure, an AI developer will need to create data and workflow. Despite a longer time-to-market, an application that transforms data, that creates workflow, that enables collaboration, and drives automation is in a great position to both create and capture meaningful value. I am spending a lot of time on these solutions today.

For example, consider construction administration for architects and engineers. Today, architects use excel and Outlook. Consider an application that reads these sources, transforms the data and uses it as a basis for workflow. This application has the right to inject other AI-use cases into the workflow, such as plan review or vendor coordination.

In other cases, if the right infrastructure is in place startups may skip this step. (Beware of sitting sit on top of someone else's data or workflow. These applications may create value but can lack long-term durability.)

Cultural readiness

Technical infrastructure is necessary but not sufficient. Change management is often harder (more ambiguous) than tech development.

Cultural readiness describes an organization's willingness to experiment with new technology. It's defined by the perceived complexity and criticality of the task undergoing digitization. The higher the C^2 score, the more friction to adoption.

For example, consider the IoT craze 7-10 years back. AI-driven predictive maintenance solutions were all the craze. However, very few (if any) flourished. Expert technicians would not trust the output of the models and were hesitant to adopt. The work was too critical... these machines have to work, and I know them the best! And too complex... how can this model predict what breaks! The applications that did the best here facilitated work versus replaced the technician.

Cost-benefit Considerations

An organization must have the right technical infrastructure and cultural readiness in place. The solution must have the right ROI to make sense. In the context of AI,

Benefits may include improvements in efficiency (or throughput), quality, or have the ability to unlock additional capabilities.

Costs may include upfront (time and capital), ongoing, and externalities such as increased risk, changing workforce needs, etc.

Types of Cost-Benefit & Product Implications

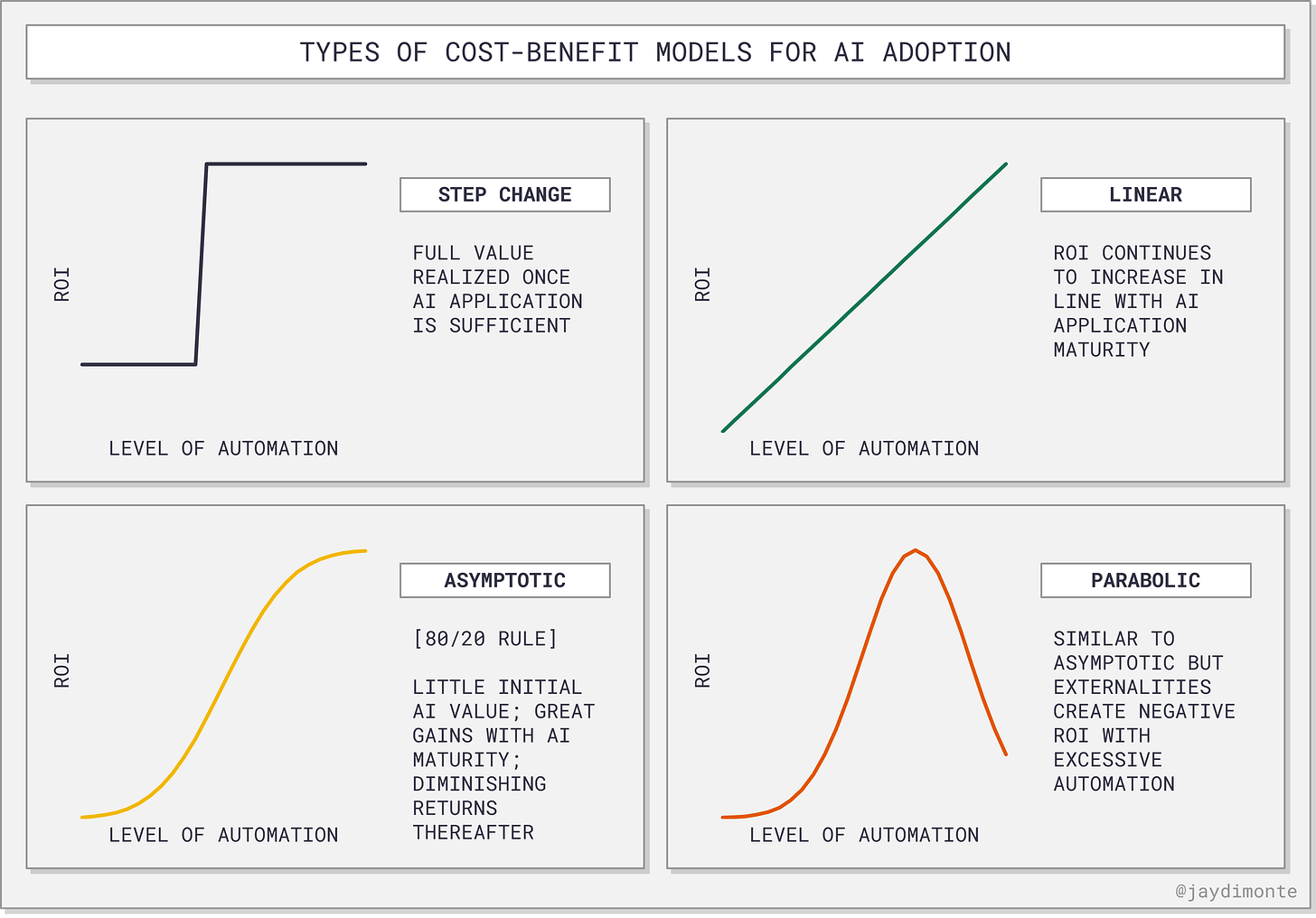

There are four types of cost-benefit relationships for adopting AI applications:

Step change (AI automates)

A solution must meet 100% of requirements before implementation. Before this, the ROI is 0. After, the ROI is completely realized. Consider anything safety-related or things like data entry.

In these cases, startups must approach the market with a complete product.

Linear (AI assists)

When AI serves as a copilot to workers, ROI increases as the application improves or with more use-cases.

In these cases, startups can start with a small "wedge" use-case and build from there.

Asymptotic (AI augments)

Sometimes, the initial AI application does not add much value... until it does. When a critical mass of the workflow is automated, the solution becomes valuable.

In these cases, startups should heed the 80/20 rule. Can you automate 80% of the use cases and allow workers to focus on the 20% exceptions?

Parabolic (AI assists or augments)

Similar considerations as the asymptotic category. But, instead of the last 20% being hard to develop, the last 20% becomes too costly to implement.

Too much automation becomes a blocker for customer adoption.

In these cases, startups should realize that perfection is the enemy of good. Startups that focus on the right automation may win against perfect automation.

Strategies for Selling ROI

In a time when many AI applications are entering the market at the same time, it is critical to identify the right product to build and the right positioning to sell.

This is particularly important in industrial sectors where you have one shot to get it right.

Too many founders think the positioning is, "You have four people doing this job and now you only need two."

What if this is a family business and the CEO doesn't want to fire their aunt?

What if this business has too much demand and would have six people running that function if they could?

What if you anchor your value to the reduction of an FTE which limits your ACV?

Founders need to consider their customers' incentives and develop their ROI accordingly.

Consider examples across the different ROI types.

Step change

Consider Supply Chain Suz. Instead of manual data entry, an application reads data, processes it, and writes it to a system of record. AI automates this task.

ROI considerations include:

Efficiency/Cost Reduction — what is the reduction in hours spent on data entry? Can workers spend their time on more valuable tasks?

Quality/Risk Reduction — if we can prove AI is 100% accurate where humans are only 85%, what mistakes can we avoid? What are the reproductions of those mistakes? Can we measure the lost revenue or extra time/capital wasted remedying the mistake?

New Infrastructure — in cases where this data was inaccessible before, an AI application may be key to building basic operational workflow. What is that value?

Linear

Consider QC Tech Ted. If Ted is more efficient, product gets out the door faster. Every improvement in Ted's efficiency translates to better revenue cycles. This automation starts small but can grow over time as the product gets better and better.

Linear ROI is best applied in situations where demand outstrips supply.

ROI considerations include:

Growth and Margin — Can we improve operations and drive revenue? Can we employ lower-skilled workers and help them operate at the same efficiency and quality levels as experts?

Today vs. Tomorrow — Something to look out for here is current versus potential revenue. Your early customers may have much lower ACVs given early product capabilities. You must reassess the value your product delivers. Maybe you need more dynamic pricing (or something that is closer to usage based versus SaaS).

Asymptotic

Back to Supply Chain Suz. 80% of her work can use AI - the data entry, identifying discrepancies, etc. - and AI is well suited to do it. The other 20% - scheduling, communicating with other teams, managing exceptions (yelling at suppliers!) - is difficult or impossible for AI to do.

Pursuing total automation is juice not worth the squeeze.

Beware of seeking too much automation. You may spend too much time developing solutions for edge cases that workers are better suited to address.

ROI considerations include:

Quality and Throughput — Quality improves when experts spend more time on high-value work, including exceptions management. Novices have guardrails in place. Seek out examples where experts could not address issues and that led to revenue loss. Sell against that.

Consider the state of the workforce, especially if an employer worries about a few key workers. How do you reduce the reliance on individuals that can walk out the door at any time? Can you sell risk-mitigation too?

Parabolic

Now, QC Tech Ted. When AI augments the inspection process, Ted becomes faster and better. Wouldn't it be even faster and better if we get rid of Ted? After all, AI is doing almost all the work!

Consider what you need to automate away Ted. It's a whole lot! More integrations. A robotic arm. A scheduling system. More coordination of machines.

The upfront installation costs go way up. Risk of operations increases. Also, instead of Ted running a camera, we need to retrain Ted to program and maintain the robotic arm.

Technically, these are doable. But the cost to the customer is too big, and they say it's not worth it.

ROI considerations here are like those of asymptotic use cases. However, because customer preferences drive adoption, spend time understanding where customers get uncomfortable. What is their technical readiness? Cultural readiness?

The key in each of these cases is to discover customer's incentives. Align the product you build and the ROI you sell to those incentives. Rarely is it a simple "RIF" and replace.

Final Thoughts on the Integration of AI in Industrial Settings

Founders that take a thoughtful approach and meet their customers where they are will be better positioned than those tackling the industry with AI as a blunt tool.

AI can assist workers, can augment their behavior, and automate away work that is dirty, dull, dangerous… or work where humans are simply not good.

Not all work should be automated equally. Founders must be deliberate in the AI applications they build and how they position them for adoption.

I am excited for AI adoption by industrial companies. People are at the center of everything we do; investors and entrepreneurs alike need to remember that.

If we can help industrial workers operate at top of license, we will have more productive industries, more profitable companies, and more fulfilled workers.